In Nanchang during June, the aroma of rice noodles fills the air. Today, the 2025 Rice Noodle Industry Trade Fair (formerly known as the "China Rice Noodle Festival") officially opened at the Nanchang Greenland International Expo Center! 500 enterprises from 21 provinces, municipalities, and regions across China, as well as from overseas, have gathered in this "hero city" for this grand gathering of the rice noodle industry.

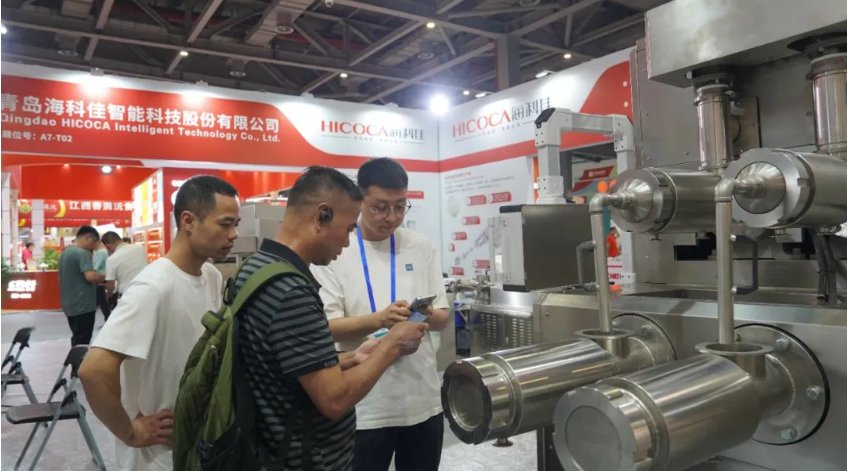

As the most influential professional exhibition in China's rice noodle industry, this year's Rice Noodle Festival was not only a feast for lovers of various types of rice noodles (stir-fried, soup, boiled, etc.), but also a platform for showcasing cutting-edge technologies and innovative equipment for the rice noodle industry. Among the many exhibitors, Qingdao Haitejia Intelligent Technology Co., Ltd. (Booth No. A7-T02) made a stunning appearance with its revolutionary equipment, igniting a "revolution in rice noodle production"!

A breakthrough moment: Haitejia's debut of its "rod pulling and bundling technology" stunned the audience.

At 10:00 a.m., the "premiere and showcase" segment of the opening ceremony became the focus of everyone's attention. Li Aiguo, the general manager of Qingdao Haitejia Intelligent Technology Co., Ltd., took the stage and delivered a key-note speech titled "Breaking Through Traditional Barriers with Automated Equipment: Reconfiguring the Rice Noodle Industry Landscape."

“Traditional rice noodle production faces three major challenges: high energy consumption, high labor costs, and significant efficiency bottlenecks.” Mr. Li pointed out the industry's difficulties, adding, “The third-generation automated rice noodle production line and the rod-pulling and bundling technology developed by Haitejia over three years is the key to overcoming these challenges!”

This revolutionary technology achieves three major breakthroughs:

→ 40% reduction in energy consumption: The innovative heat recovery system significantly reduces steam consumption during the drying process.

→ 50% reduction in labor costs: Automated bundling systems replace traditional manual bundling.

→ 60% increase in efficiency: Continuous production ensures seamless operation from rice washing to cutting.

“This means that rice noodle manufacturers will gain a competitive advantage with cost reductions of over 30%!” Mr. Li's statement drew thunderous applause from the audience.

At the exhibition, Haitejia's booth (A7-T02) attracted numerous professional buyers with its innovative technology. According to official reports, its three core pieces of equipment—the 400-type rice noodle extruder, the 240-type block-shaped extrusion production line, and the 40kg rice noodle pilot production line—became a focal point of the exhibition due to their ability to address industry pain points (such as intelligent control to reduce labor intensity and providing solutions for research institutions to conduct theoretical and technological research on rice noodles). Rice noodle manufacturers from all over the country inquired about the technical details, and there were frequent queues of visitors waiting to speak with the staff at the booth.

|  |

|  |

As the executive chairman of the Rice Noodles Industry Sub-Alliance, Haitejia has been deeply involved in the rice noodle equipment industry for over a decade. In August last year, at the National Rice Alliance Rice Noodles Industry New Quality Productivity Development Forum, Mr. Zheng, Vice Chairman of Haitijia, stated that "equipment innovation is the engine of industry upgrading."

This concept has yielded positive results across the country:

√ In Xiajiang, Jiangxi: Completed the intelligent transformation of a small-scale rice noodle workshop in Longxia, increasing daily production capacity to 500 catties and overcoming weather-related limitations in the drying process;

√ In fresh rice noodle production bases: Provided technical support for aseptic production lines to members of the sub-alliance;

√ In large-scale factories: Promoted the implementation of automated production lines with a daily output of 30 tons.

Local governments have pointed out that technological empowerment is driving the transformation of traditional industries into "smart manufacturing"!

The rice noodle industry is entering a new era of "intelligent manufacturing."

With numerous instant noodle brands achieving annual sales exceeding 100 million yuan, the Jiangxi rice noodle industry is rapidly accelerating. Automated equipment is a key factor in this industry upgrade.

At the exhibition, an experienced craftsman with 20 years of experience, after observing Haitejia's equipment, remarked, "Traditional craftsmanship must be preserved, but we must also embrace modern technology! Without these machines, Jiangxi rice noodles wouldn't be able to reach the global market."

Just as Haitejia believes—technology and quality for global manufacturing! When the millennia-old tradition of rice noodles meets intelligent technology, the story of a bowl of rice noodles is writing a new legend...

Come and experience it for yourself!

→ Date: June 13-15

→ Location: Nanchang Greenland International Exhibition Center, Booth A7-T02

Let's meet in Nanchang, the "Hero City," and witness the intelligent transformation of a bowl of rice noodles!

[END]