1、Voltage: 220V

2、Frequency: 50Hz

3、Power: 13kw

4、 Gas consuming: 30L/min

5、 Weighing accuracy: 200-500g within 2g; 500-1000g within 3g

6、 Weighing speed: 30-50 times/min

7、 Bundling spec: 200-250g/bundle, 4-5 bundle/bag; 75-150g/bundle, 4-5bundle/bag

8、Packing combination: 200-250g/bundle, 4-5bundles/bag; 75-150g/bundle, 4-5bundles/bag

9、Weight for one package : 360-1000g

10、Bundling speed:10-25 bundles/min

11、Packing speed: 30-50 bags-min

12、Bundle style: single bundle/ Twin bundle

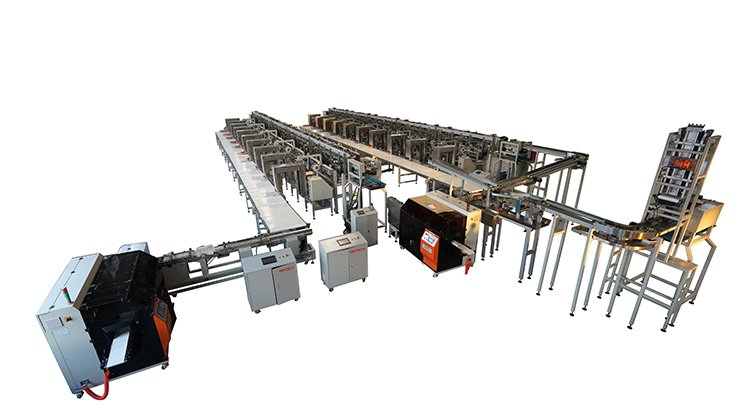

13、Equipment size: 20000*4500*2200mm (8 scales)

This line is used to pack noodles, spaghetti, pasta or products with similar shape as them with the length from 180mm to 240mm. Automatically complete the process of weighing-scale, bundling-bundling machine, lifting-lifting machine, feeding-feeding system, trim-conveyor packing-packing machine.

Site requirements: The equipment should be established inside the room with flat floor. No shaking and bumping.

Floor requirements: it should be hard and non-conductive.

Temperature: -5~40℃

Relative humidity: <75%RH, no condensation.

Dust: no conductive dust.

Air: no flammable and combustible gas or objects,no gas which can make damage to mental.

Altitude: under 1000 meters

Ground connection: safe and reliable ground environment.

Power grid: stable power supplying, and volatility within +/-10%.

Other requirements: keep away from rodents