一、Production line Equipment Contains:

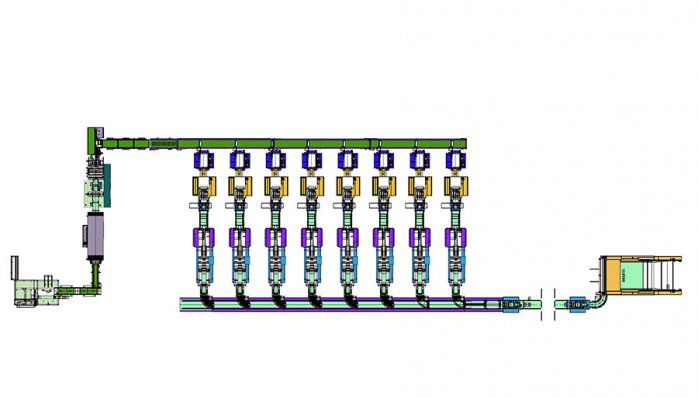

High precision Automatic Noodle cutting machine-Conveyor Type Feeding System-Weighing Machine-Bundling Machine-Hoist checkweigher -High Tightness paper packing machine-Sealing Machine-robot reversing Equipment - semi-finished conveyor - material, feeding device - fork conveyor line - reciprocating shrink film packaging machine - shrinking furnace - paper bag flat pocket - robot palletizer.

二、production line process:

The whole rod Noodle from the drying room enters the high-precision cutting machine and is intelligently cut according to the preset length.The cutted Scattered Noodle into the weighing machine stations through the intelligent Conveyor Type Feeding System. After accurate weighing by each weighing machine, it will enter the bundling machine station for bundling.The bundled materials are weighted by the Hoist checkweigher, and the unqualified materials are automatically removed and transported to the designated location for re-weighing. Qualified materials enter the High Tightness paper packing machine for automatic roll Packaging.After packaging, the semi-finished products will automatically enter the general sealing machine for chamfering and sealing.The semi-finished products after sealing are sorted by the semi-finished conveyor and Balling Machine and automatically fed into the fork conveying line through the reciprocating shrink film packaging machine, and then sent to the shrinking furnace for shrinking and setting.The finished single-package product is packed into a paper bag flat pocket machine for large bag packaging.The packaged large bag finished product is sent to the palletizing area via the finished conveyor, and is palletized by the palletizing robot, and then sent to the finished product warehouse to complete the entire production process.

三、production line economic benefit analysis:

The paper-packed reciprocating shrink film automatic production line (taking the standard eight-station as an example), the degree of automation is significantly improved.Compared with the traditional artificial production line, the curved intelligent feeding system can save 2 people per shift; the High Tightness paper packing machine replaces the manual roll paper packaging, saving 12 people per shift; fork conveying line, reciprocating Shrink film packaging machine, shrinking furnace, can save 3 people per shift; paper bag flat pocket bagging machine can save 2 people per shift; robot palletizer can save 1 person per shift; Totally can save 20 people per shift.

Our company's new paper packaging reciprocating shrink film automatic production line, high degree of automation, high concentration of electrical control.The equipment is versatile and can be automated for all product types from 300 to 1000 grams.Moreover, the equipment has high flexibility in configuration, the Noodle manufacturer can choose according to the production capacity of the production line and the market sales. You can choose either Six-Weigher paper packaging reciprocating shrink film automatic or a eight-weigher packaging reciprocating shrink film automatic. We have more than 30 customers in China using this Equipment, The Equipment currently works well, which greatly saves the labor cost of the Manufacture,greatly benefits the energy saving and consumption reduction of the noodle enterprises.